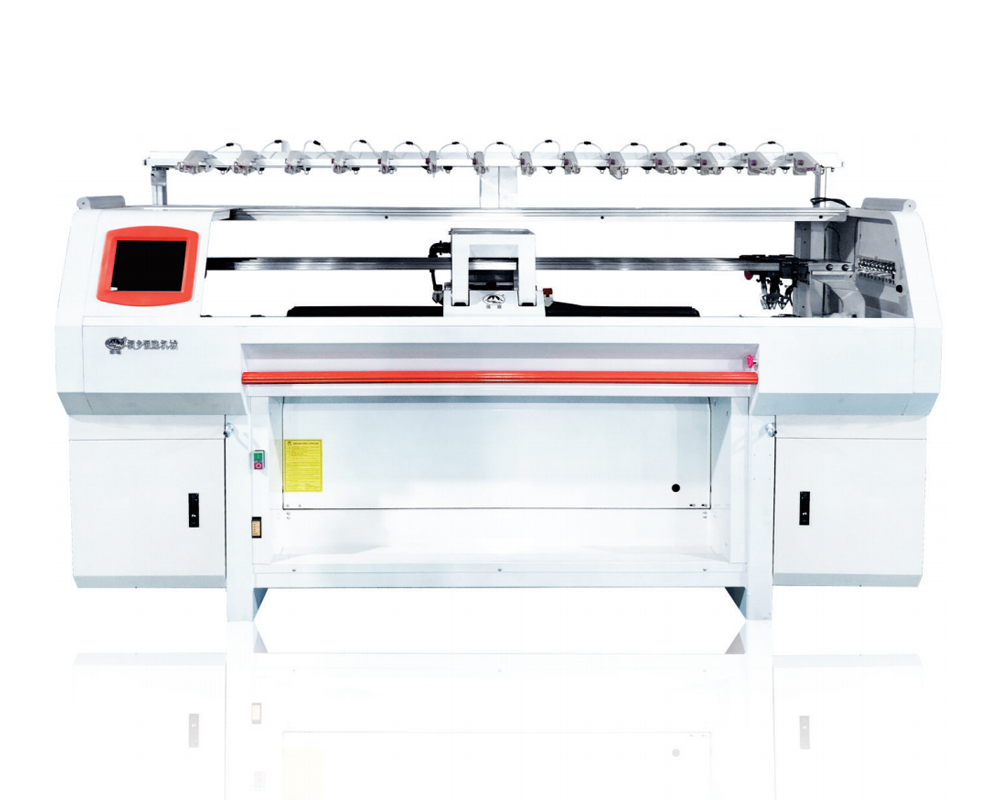

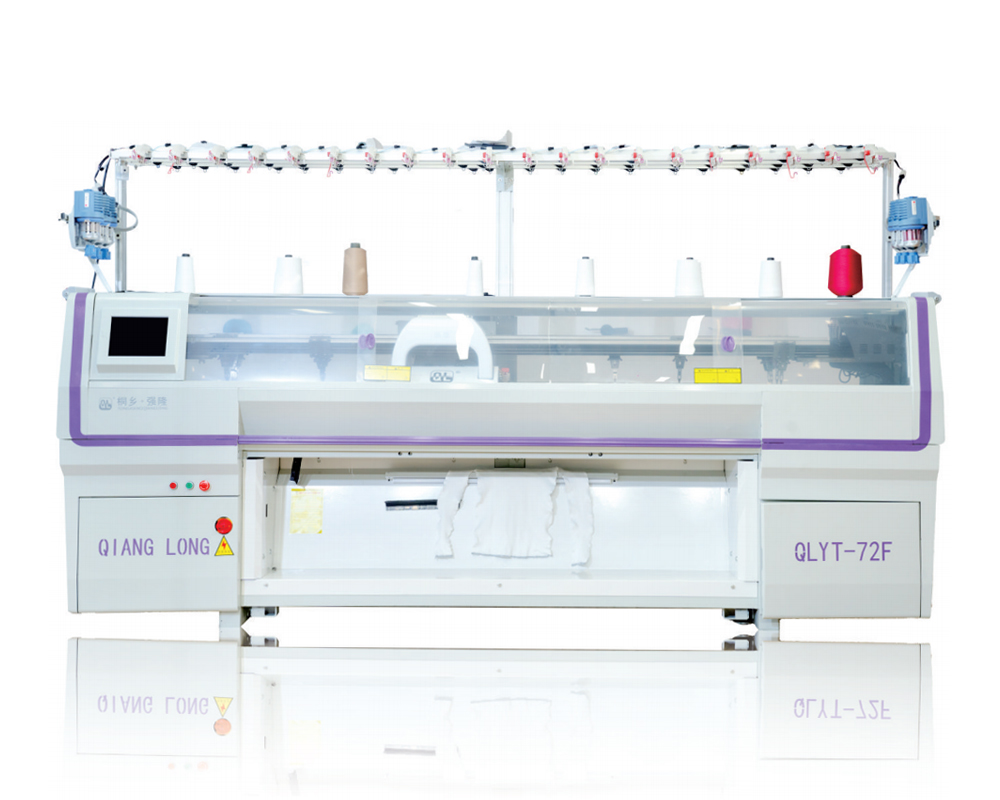

Tongxiang Qianglong Machinery Co., Ltd. is high-tech China wholesale computerized flat knitting machine manufacturers, specialized in designing, developing, and manufacturing Knitting Machinery..

In the rapid development of modern textile technology, 3D Flyknit Knitting Machine (3D Flyknit Knitting Machine), as an innovative intelligent loom equipment, is completely changing the production methods of footwear, sportswear and textile industries. It achieves seamless weaving and precise control by using 3D weaving technology and fly weaving technology, thereby achieving significant improvements in comfort, design freedom and production efficiency.

Fly knitting technology refers to the use of computer programming control and the use of high-precision needle beds and yarn delivery systems to weave fiber materials into integrated fabrics according to preset textures and structures. Compared with traditional looms, the 3D Flyknit Knitting Machine can achieve more complex weaving structures and pattern designs without the need for stitching.

3D weaving technology enables machines to weave fabrics in multiple directions to form a three-dimensional structure. By precisely controlling knitting density and material arrangement, the 3D Flyknit Knitting Machine can enhance elasticity, support or breathability in specific areas as needed. This technology is not only suitable for making shoe uppers, but can also be used for complex clothing or industrial textile production.

The operation of the 3D Flyknit Knitting Machine relies on computer-aided design (CAD) and knitting control systems. Designers can create complex weaving patterns and structures through software tools and input design data into machines for weaving. This kind of weaving control makes the production process more automated and efficient, while reducing manual operation errors.

The 3D Flyknit Knitting Machine can weave materials into a seamless integrated structure, avoiding the stitching steps required in traditional fabric processing. This not only reduces processing time and material waste, but also improves the comfort and durability of the finished product.

Compared with traditional looms, 3D Flyknit Knitting Machine is more efficient in the production process. It can adjust the weaving density and structure according to needs, minimize yarn consumption and reduce material waste. In addition, automated weaving can also significantly reduce labor costs and improve production efficiency.

Since the weaving process is controlled by a computer, designers can freely adjust the weaving structure and pattern of the fabric according to customer needs to achieve personalized customized designs. 3D Flyknit Knitting Machine can quickly respond to market changes and provide brands with more flexible product development and production solutions.

3D Flyknit technology can be designed according to ergonomics and differentially knitted for different parts such as uppers and clothing. For example, it can provide support in the upper area while maintaining breathability and softness in the instep area, thereby improving the wearer's comfort. For sportswear, this technology can add support or elasticity in key areas to improve performance.

Since the 3D Flyknit Knitting Machine reduces material waste during the production process and reduces cutting and sewing processes through seamless weaving, the environmental impact of textile manufacturing is significantly reduced. In addition, flywoven materials usually use environmentally friendly materials such as recyclable polyester fiber, which helps achieve the goal of sustainable development.

3D Flyknit Knitting Machine is widely used in footwear manufacturing, especially in the upper production of sports shoes and casual shoes. Through integrated seamless weaving, the upper can accurately fit the shape of the foot, providing better support and comfort. At the same time, the 3D woven structure can adjust the breathability and elasticity according to needs, making the shoes more suitable for various sports scenes.

In the field of sportswear, 3D Flyknit Knitting Machine is used to manufacture high-performance sportswear, such as running shirts, yoga clothes, and fitness clothes. By adjusting the weaving density in different areas, this technology can enhance the support and elasticity of sportswear in specific areas, and improve heat dissipation and breathability. In addition, functional clothing such as outdoor equipment, medical pressure clothing, etc. can also improve functionality and comfort through 3D Flyknit technology.

In addition to clothing and footwear, the 3D Flyknit Knitting Machine can also be used to manufacture home textiles and industrial textile materials such as cushions, carpets, and filters. These products have high requirements on the structure and durability of the fabric, and 3D Flyknit weaving technology can adjust the performance of the material according to specific needs.

In the medical field, 3D Flyknit Knitting Machine is used to manufacture medical auxiliary products, such as elastic bandages, braces and orthotics. Through personalized woven designs, these products can provide precise support and pressure distribution to help patients recover better.

The emergence of 3D Flyknit Knitting Machine marks the textile industry's move towards intelligent manufacturing. Automated and digital weaving technology not only improves production efficiency, but also promotes the development of integrated textile design and manufacturing, allowing companies to better respond to changes in market demand.

With 3D Flyknit technology, companies can reduce material waste and production steps, thereby optimizing supply chain management. This technology can also shorten the product development cycle, allowing companies to bring new products to market faster, thus improving competitiveness.

Since the 3D Flyknit Knitting Machine supports personalized customization and complex designs, the innovation and diversity of textiles have been greatly improved. Brands can be more flexible in product development and provide consumers with more attractive options.

The emergence of 3D Flyknit Knitting Machine has brought revolutionary changes to the textile industry. By combining 3D knitting technology with fly knitting technology, this innovative knitting machine not only improves production efficiency and product quality, but also promotes the intelligent and personalized development of textile technology. With the continuous advancement of technology and the growth of market demand, 3D Flyknit Knitting Machine will play an important role in a wider range of application fields, injecting more vitality into the future of the textile industry.

English

English 简体中文

简体中文

Chinese

Chinese English

English