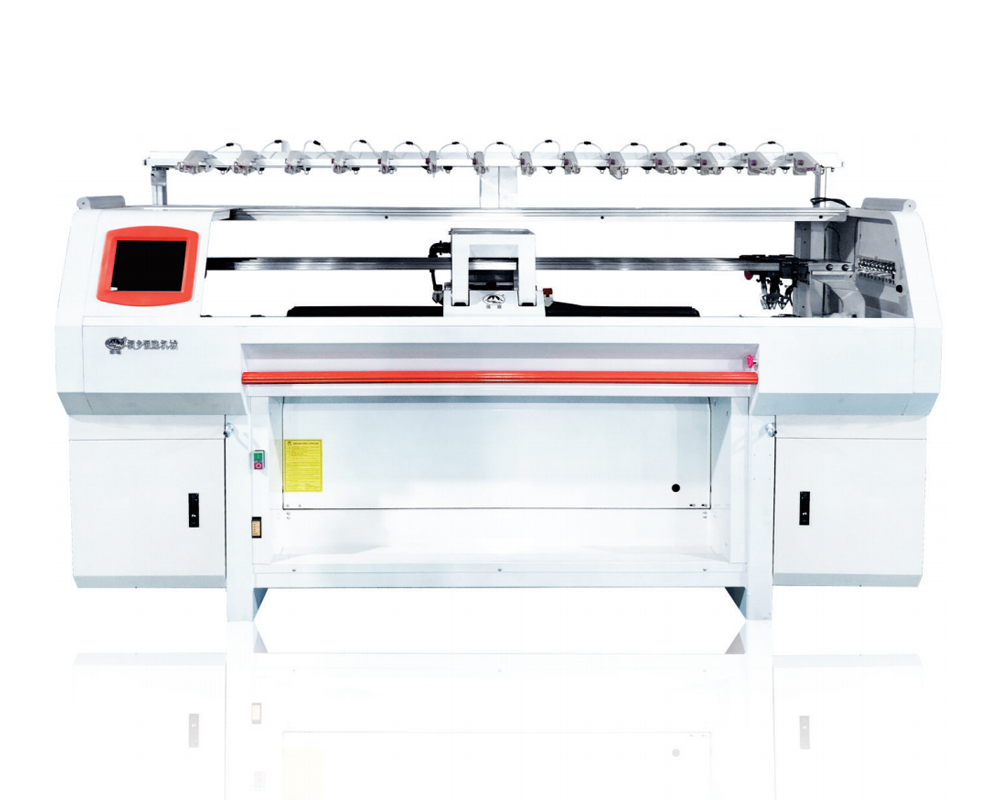

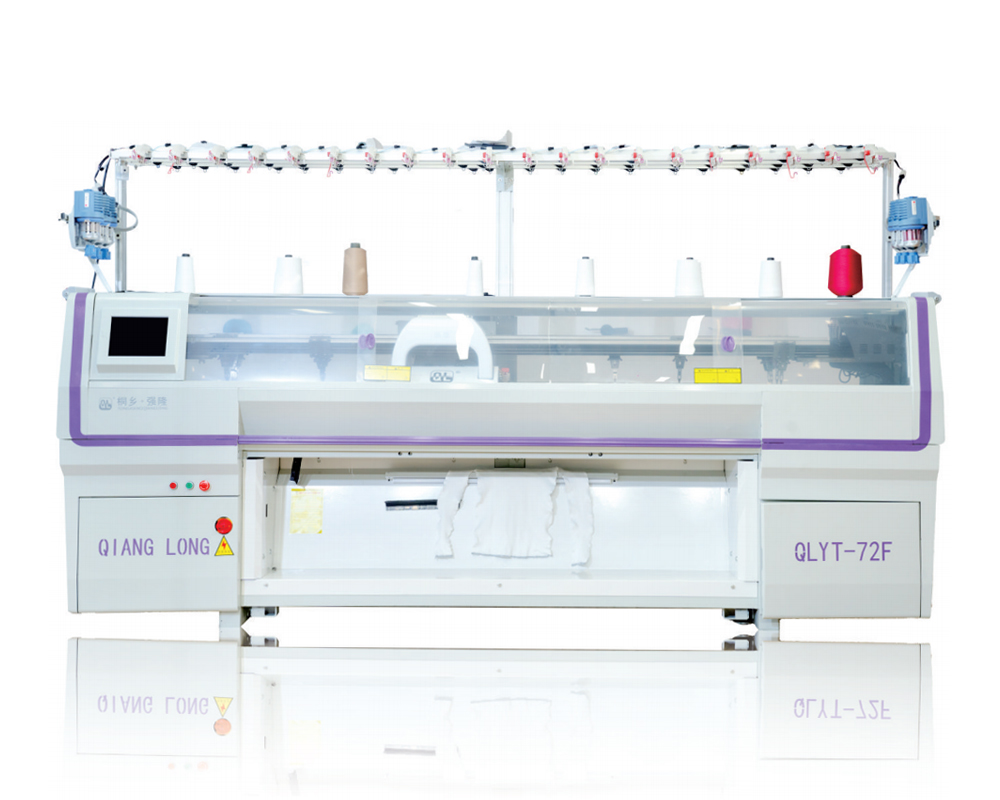

Tongxiang Qianglong Machinery Co., Ltd. is high-tech China wholesale computerized flat knitting machine manufacturers, specialized in designing, developing, and manufacturing Knitting Machinery..

Collar knitting machines can often be upgraded or modified to enhance their capabilities. These modifications can improve performance, increase versatility, and extend the machine's lifespan. Here are some common upgrades and modifications for collar knitting machines:

1. Software and Control System Upgrades

Advanced Pattern Programming: Upgrading to more sophisticated software can allow for more complex and intricate patterns, including custom designs and detailed jacquard knitting.

Touchscreen Interface: Installing a modern, user-friendly touchscreen interface can simplify machine operation and reduce setup times.

Connectivity: Adding network capabilities to connect with other machines or central management systems for better coordination and monitoring.

2. Hardware Enhancements

Additional Feeders: Installing more yarn feeders can allow for the use of multiple yarns simultaneously, enabling more complex and colorful designs.

Improved Needle Beds: Upgrading to double needle beds can expand patterning capabilities and allow for thicker, more complex fabrics.

Automatic Yarn Changers: Adding or upgrading automatic yarn changers can reduce downtime and increase efficiency when switching between different yarns.

3. Quality and Efficiency Improvements

Enhanced Tension Control: Upgrading the tension control system can improve stitch consistency and fabric quality.

Automatic Lubrication System: Installing an automatic lubrication system can reduce maintenance requirements and prolong the machine’s lifespan.

Waste Yarn Disposal Systems: Implementing systems for the disposal of waste yarn can maintain cleanliness and reduce defects.

4. Environmental and Energy Efficiency

Energy-Efficient Motors: Replacing old motors with energy-efficient ones can reduce energy consumption and lower operating costs.

Noise Reduction Modifications: Installing noise-dampening components can make the machine quieter, improving the working environment.

5. Specialized Attachments and Accessories

Intarsia Carriage: Adding an intarsia carriage allows for more intricate color work and patterning, expanding the creative possibilities.

Plating Attachments: These attachments enable the use of multiple yarns in a single course, creating unique textures and color effects.

Seamless Knitting Attachments: Modifications that allow for seamless knitting can produce garments without seams, improving comfort and appearance.

6. Training and Technical Support Enhancements

Operator Training Programs: Investing in advanced training programs for operators can maximize the efficiency and capabilities of the machine.

Extended Technical Support: Upgrading technical support packages can provide quicker resolution of issues and better maintenance routines.

7. Customization for Specific Applications

Specialty Yarn Handling: Modifying the machine to handle specialty yarns (e.g., elastic, metallic, or novelty yarns) can expand the range of products that can be produced.

Adjustable Stitch Density: Enhancements that allow for easy adjustments to stitch density can enable quick changes between different types of fabrics.

Implementation Considerations

Compatibility: Ensure that any upgrades or modifications are compatible with the existing machine model and its components.

Cost-Benefit Analysis: Evaluate the cost of upgrades against the potential benefits in terms of increased productivity, improved quality, and expanded capabilities.

Vendor Support: Work with the machine's manufacturer or authorized vendors to ensure upgrades are professionally installed and supported.

Training: Provide adequate training for operators to effectively utilize new features and technologies.

Collar knitting machines can be significantly enhanced through various upgrades and modifications. These improvements can range from software updates and hardware enhancements to specialized attachments and environmental efficiency modifications. By implementing these upgrades, manufacturers can increase the versatility, efficiency, and quality of their collar knitting operations, ensuring they remain competitive in the market.

English

English 简体中文

简体中文

Chinese

Chinese English

English