Tongxiang Qianglong Machinery Co., Ltd. is high-tech China wholesale computerized flat knitting machine manufacturers, specialized in designing, developing, and manufacturing Knitting Machinery..

In the modern textile industry, the collar knitting machine (Collar Knitting Machine), as a device specially used to produce knitted collars, has become one of the key equipment for knitted garment production due to its high efficiency, precision and diversified knitting capabilities. The collar is an important part of knitted garments, which not only affects the overall beauty of the garment, but also directly relates to the comfort of wearing. Therefore, the application and development of the collar knitting machine is of great significance to the knitting industry. This article will discuss in detail the working principle, advantages, application fields and future development trends of the collar knitting machine.

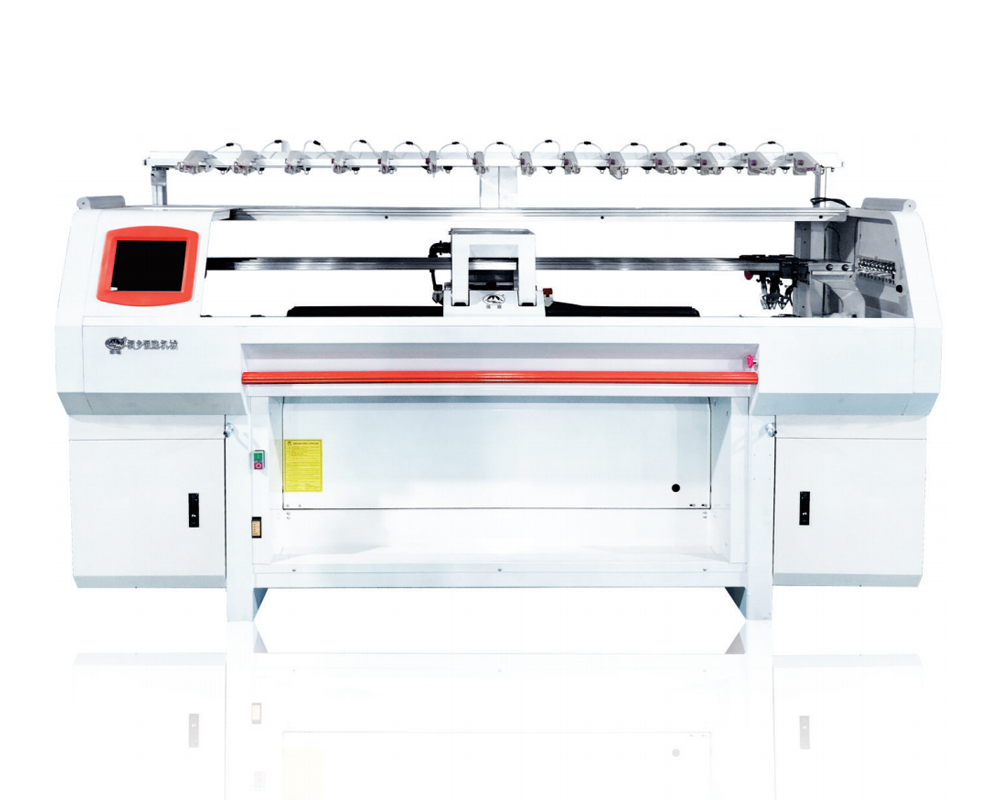

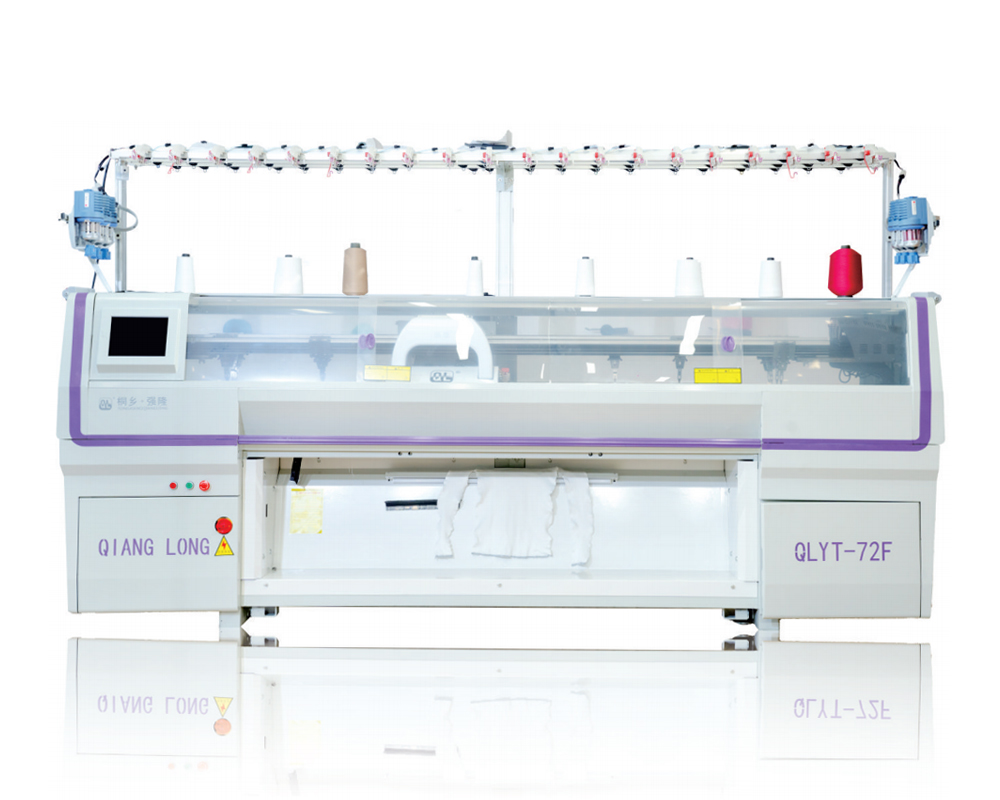

The core principle of the collar knitting machine is to accurately knit knitted collars of various styles and sizes through a computer control system. Generally speaking, the collar knitting machine is mainly composed of a knitting system, a control system and a feeding system.

The knitting system is the core part of the collar knitting machine, which is responsible for knitting the yarn according to the predetermined pattern. Modern collar knitting machines usually adopt the structure of a flat needle machine or a circular needle machine, and quickly and accurately knit the required collar shape through a needle plate and a yarn guide device.

The control system can accurately control every step of the knitting process through pre-programming. This system usually adopts advanced computer control technology, supports automatic switching and adjustment of multiple knitting patterns, and greatly improves production efficiency and product diversity.

The feeding system is responsible for delivering the yarn to the knitting system evenly and stably. Modern collar knitting machines are usually equipped with multi-axis feeding devices, which can handle a variety of yarns of different colors and materials at the same time to achieve rich knitting effects.

The collar knitting machine can quickly and efficiently produce various types of knitted collars, and the production speed is far faster than traditional manual knitting. Automated operation allows the production line to work uninterruptedly, greatly improving production efficiency and meeting the needs of large-scale production.

Thanks to the advanced computer control system, the collar knitting machine can accurately control the density and pattern of each needle during the knitting process to ensure that the size and shape of each collar fully meet the design requirements. The precise knitting ability not only improves the quality of the product, but also reduces the scrap rate.

Modern collar knitting machines support the knitting of multiple knitting modes and patterns, and can produce a rich variety of collar styles according to different design requirements. Whether it is a simple plain collar or a complex pattern collar, the collar knitting machine can easily cope with it.

Collar knitting machines with a high degree of automation are very easy to operate. Usually, only a small number of operators are needed to monitor and maintain the machine, which greatly reduces the dependence on manual labor. At the same time, the training cost of operators is relatively low, which further reduces production costs.

The programmability of the collar knitting machine makes it highly flexible. Manufacturers can quickly adjust knitting parameters and patterns according to market demand or customer customization requirements, shorten the development cycle of new products, and enhance market competitiveness.

Collar knitting machines are mainly used in the field of knitted clothing production, including the following aspects:

Sportswear usually uses elastic knitted fabrics, and the comfort and durability of the collar are crucial. Collar knitting machines can produce high-quality collars that meet sports needs and are widely used in sports T-shirts, sweatshirts and other products.

In casual clothing, knitted collars are deeply loved by consumers for their soft and comfortable characteristics. Collar knitting machines can produce a variety of casual collars to meet the market's demand for personalization and comfort.

In fashion clothing design, unique collar designs often become the finishing touch. The diverse weaving capabilities of collar knitting machines enable designers to create a variety of creative and unique collars, enhancing the overall beauty and market competitiveness of clothing.

Uniforms and work clothes require collars to have a certain durability and standardized design. Collar knitting machines can efficiently produce collars that meet industry standards and are widely used in the production of various uniforms and work clothes.

With the continuous advancement of technology and changes in market demand, collar knitting machines will show the following trends in future development:

The future collar knitting machines will be more intelligent, integrating advanced sensors and artificial intelligence technology to achieve a fully automated production process. Intelligent knitting machines will be able to self-detect and adjust knitting parameters to further improve production efficiency and product quality.

With the increase in environmental awareness, energy-saving collar knitting machines will become the focus of future development. By optimizing design and applying energy-saving technologies, energy consumption and carbon emissions can be reduced, promoting the green development of the textile industry.

The future collar knitting machines will have more functions, such as integrating multiple knitting technologies, supporting multiple yarn materials, and achieving multiple knitting effects, to meet more complex and diverse market needs.

Modular design will make collar knitting machines more flexible. Users can freely combine and configure machines according to production needs, reduce equipment investment costs, and improve the adaptability and scalability of production lines.

As a key equipment in modern knitted garment production, collar knitting machines have become an indispensable tool for the production of various types of knitted collars with their efficient, precise and diverse knitting capabilities. With the continuous innovation of technology and changes in market demand, collar knitting machines will develop in the direction of intelligence, environmental protection and energy saving, multifunctionality and modular design, injecting new vitality into the textile industry. In the future, collar knitting machines will continue to play an important role in the global knitting market, helping textile companies improve production efficiency and product competitiveness.

English

English 简体中文

简体中文

Chinese

Chinese English

English