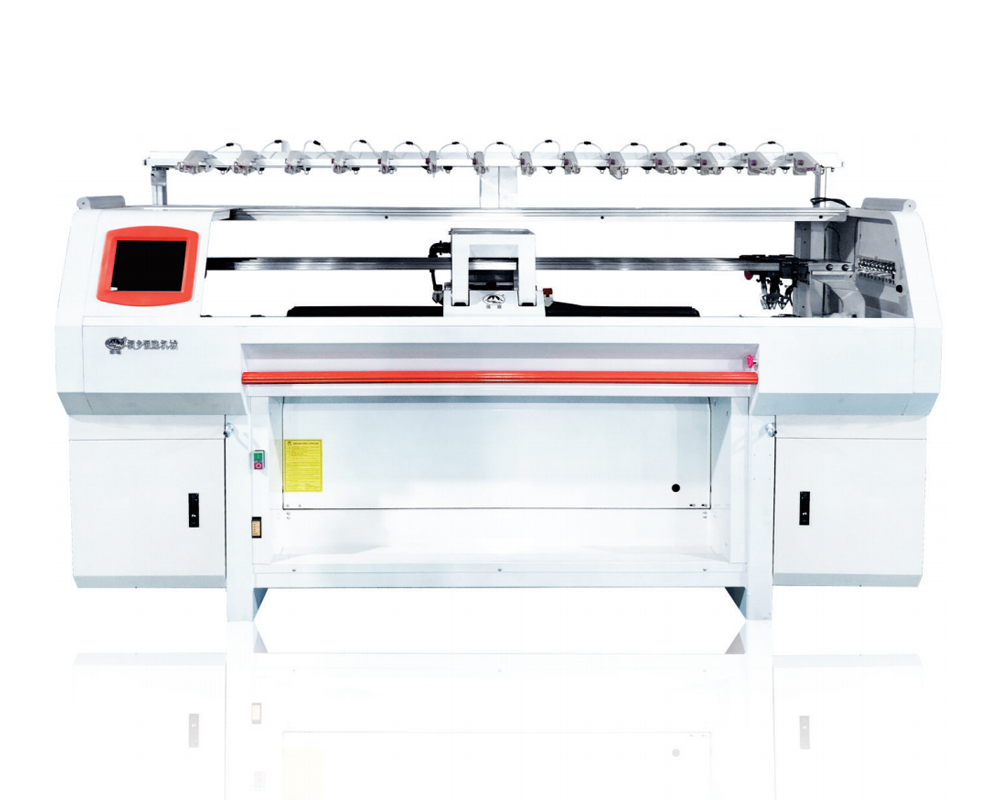

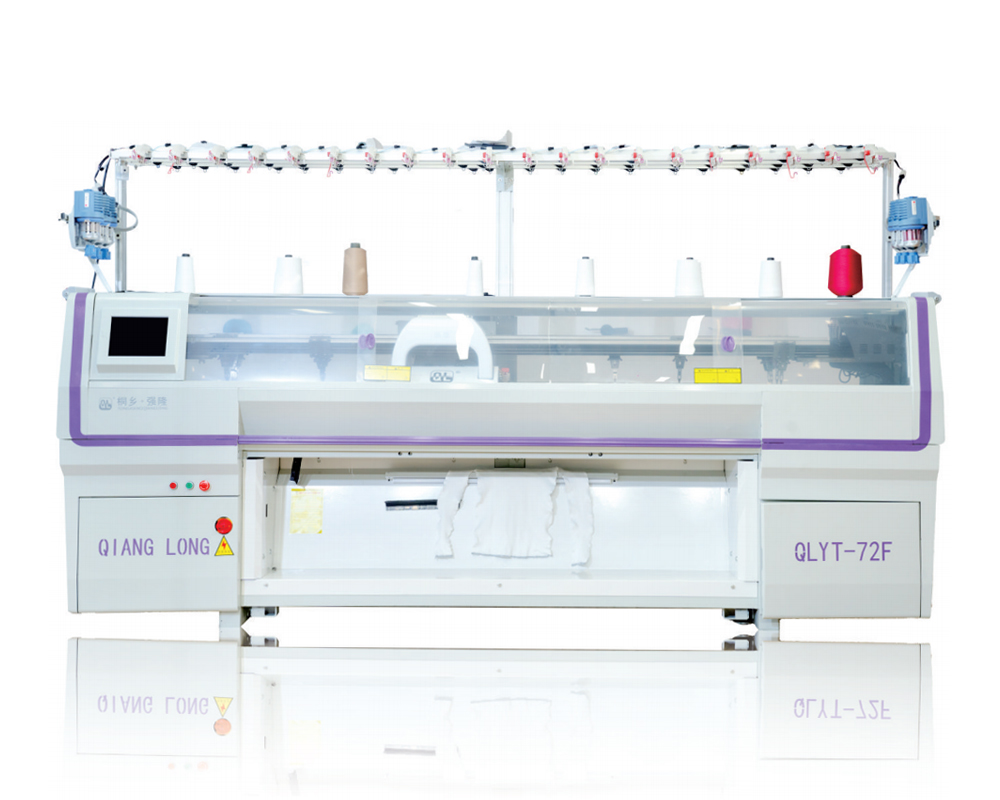

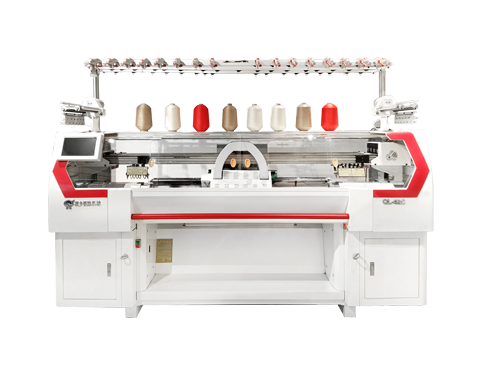

Tongxiang Qianglong Machinery Co., Ltd. is high-tech China wholesale computerized flat knitting machine manufacturers, specialized in designing, developing, and manufacturing Knitting Machinery..

Computerized knitting machines have transformed the textile industry by bringing automation, precision, and versatility to the knitting process. These machines use computer-controlled systems to create intricate knit patterns with speed and consistency that manual knitting cannot match. This article explores the technology behind computerized knitting machines, their advantages, and how they are shaping the future of textile production.

Computerized knitting machines operate using a complex system of needles, yarn feeders, and pattern programming. Unlike traditional manual knitting, where each stitch is made by hand, computerized knitting machines automate this process by following digital patterns stored in their memory.

The process begins with creating a digital design using specialized software. Designers can create intricate patterns and specify stitch types, colors, and textures. These designs are then converted into a format that the knitting machine can read, often through a USB connection or direct computer link.

Once the pattern is uploaded, the machine is set up with the necessary yarns. Different types of yarns can be loaded into the machine to achieve various effects, from simple color changes to complex textures.

The computerized knitting machine uses its needles and feeders to execute the pattern with high precision. The needles move in response to the programmed instructions, creating loops of yarn to form stitches. The machine can adjust the tension and positioning of the yarn to produce different knit structures, from basic jersey knits to intricate jacquards.

Advanced computerized knitting machines include sensors and monitoring systems that detect and correct errors in real-time. This ensures consistent quality throughout the production process, reducing waste and the need for manual intervention.

Precision and Consistency: One of the key advantages of computerized knitting machines is their ability to produce complex patterns with high precision and consistency. Unlike manual knitting, which is prone to human error, these machines can replicate designs accurately, ensuring uniformity in each piece.

Computerized knitting machines can operate at high speeds, significantly reducing production times. This efficiency allows manufacturers to meet large orders quickly and respond to market demands with shorter lead times.

The ability to program intricate patterns and adjust settings digitally gives designers greater creative freedom. Computerized knitting machines can produce a wide range of designs, from simple textures to detailed images, making them ideal for fashion, home textiles, and technical applications.

Automation reduces the need for manual labor, lowering production costs. While skilled operators are still required to set up and monitor the machines, the overall labor input is much less than that of traditional knitting methods.

By precisely controlling yarn usage and reducing errors, computerized knitting machines help minimize material waste. This not only lowers production costs but also contributes to more sustainable manufacturing practices.

Computerized knitting machines are used in various sectors of the textile industry:

In the fashion industry, these machines enable the creation of intricate knitwear, including sweaters, dresses, and accessories. Designers can experiment with different stitch patterns, textures, and color combinations to produce unique and high-quality garments.

Computerized knitting machines are also used to produce home textiles like blankets, cushions, and upholstery fabrics. The ability to create complex designs and textures makes them ideal for adding a decorative touch to interior furnishings.

Beyond fashion and home textiles, computerized knitting machines play a vital role in producing technical textiles. This includes items like medical textiles, sportswear, and industrial fabrics that require specific properties such as elasticity, breathability, and strength.

With the rise of customization in the fashion industry, computerized knitting machines offer the capability to produce made-to-order garments. Brands can offer personalized designs, colors, and fits, catering to individual customer preferences and reducing inventory costs.

The future of computerized knitting machines is promising, with ongoing advancements in technology driving further improvements:

Future knitting machines may incorporate artificial intelligence (AI) and machine learning to enhance pattern recognition and error correction. This could lead to even greater efficiency and quality control in the knitting process.

Computerized knitting machines are evolving to include 3D knitting capabilities, allowing the creation of seamless and three-dimensional structures. This innovation opens up new possibilities for designing complex garments and products with minimal seams and waste.

As the textile industry shifts towards more sustainable practices, computerized knitting machines will play a crucial role in reducing waste and energy consumption. The ability to produce garments on demand and with minimal waste aligns with the growing demand for eco-friendly fashion.

English

English 简体中文

简体中文

Chinese

Chinese English

English