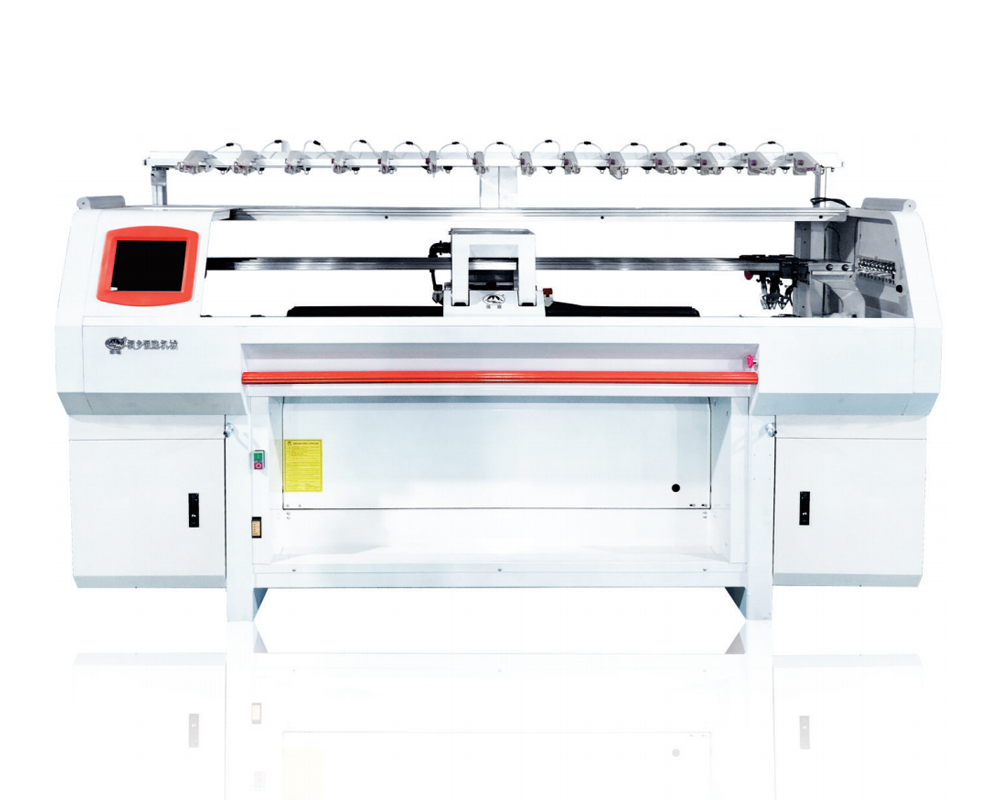

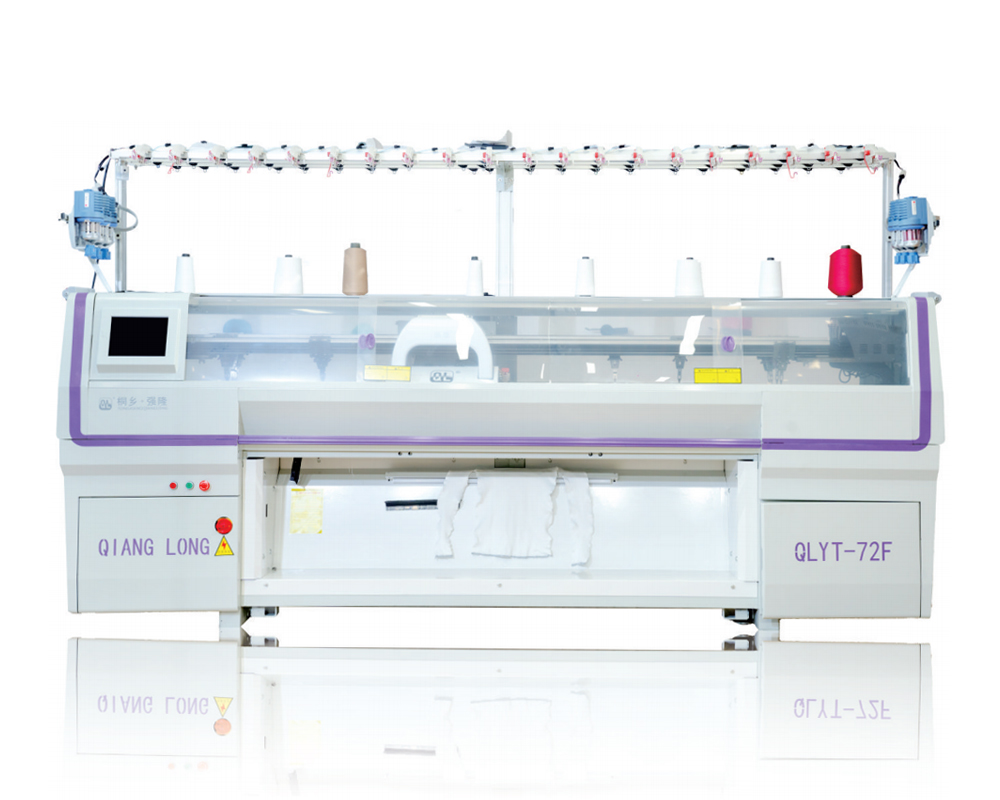

Tongxiang Qianglong Machinery Co., Ltd. is high-tech China wholesale computerized flat knitting machine manufacturers, specialized in designing, developing, and manufacturing Knitting Machinery..

Durability of Computerized Knitting Machines

Build Quality:

Computerized knitting machines are generally built to be robust and durable, especially those designed for industrial use. They are made from high-quality materials that can withstand continuous and intensive use.

Domestic models, while not as heavy-duty as industrial machines, are also designed to be durable for regular home use.

Component Longevity:

The electronic components, such as the computer system and motors, are designed to last for many years. However, their longevity can be affected by factors like usage intensity and environmental conditions.

Mechanical parts like needles, needle beds, and yarn feeders are typically made from strong materials, but they may need to be replaced periodically due to wear and tear.

Maintenance Requirements

Regular Cleaning:

Regular cleaning is essential to keep the machine running smoothly. This includes removing lint, dust, and yarn debris from the needle bed, yarn feeders, and other components.

Lubricating moving parts as recommended by the manufacturer helps prevent wear and ensures smooth operation.

Software Updates:

Updating the machine’s software ensures it runs efficiently and can handle new patterns and functionalities. Manufacturers often provide updates to improve performance or fix bugs.

Periodic Inspection:

Regularly inspect the machine for signs of wear or damage, particularly in high-use areas like the needle bed and yarn feeders.

Check electronic components for any signs of malfunction or wear.

Needle and Part Replacement:

Needles can become dull or damaged over time and should be replaced as needed.

Other parts, such as needle beds, yarn feeders, and tension guides, may also need periodic replacement.

Calibration and Tension Adjustment:

Regularly calibrate the machine to ensure it is knitting accurately and consistently.

Adjust the yarn tension settings to accommodate different yarn types and project requirements.

Professional Servicing:

Periodic professional servicing can help maintain the machine in optimal condition. A professional can thoroughly clean, inspect, and tune the machine.

Industrial machines, in particular, may require professional maintenance to ensure they continue to operate at peak efficiency.

User Manual and Manufacturer Guidelines

Following the maintenance schedule and guidelines provided in the user manual is crucial. Each model may have specific requirements and recommendations for optimal care.

Manufacturers often provide detailed instructions on routine maintenance tasks and troubleshooting common issues.

By adhering to these maintenance practices, a computerized knitting machine can remain reliable and functional for many years, providing consistent high-quality knitting results.

English

English 简体中文

简体中文

Chinese

Chinese English

English