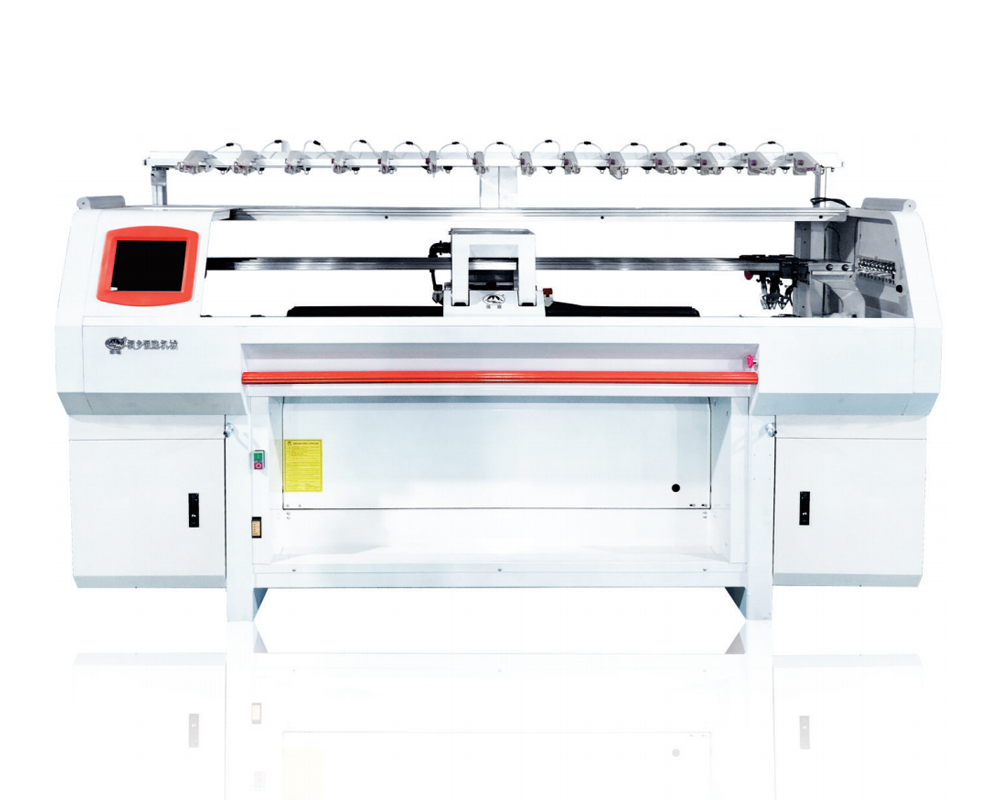

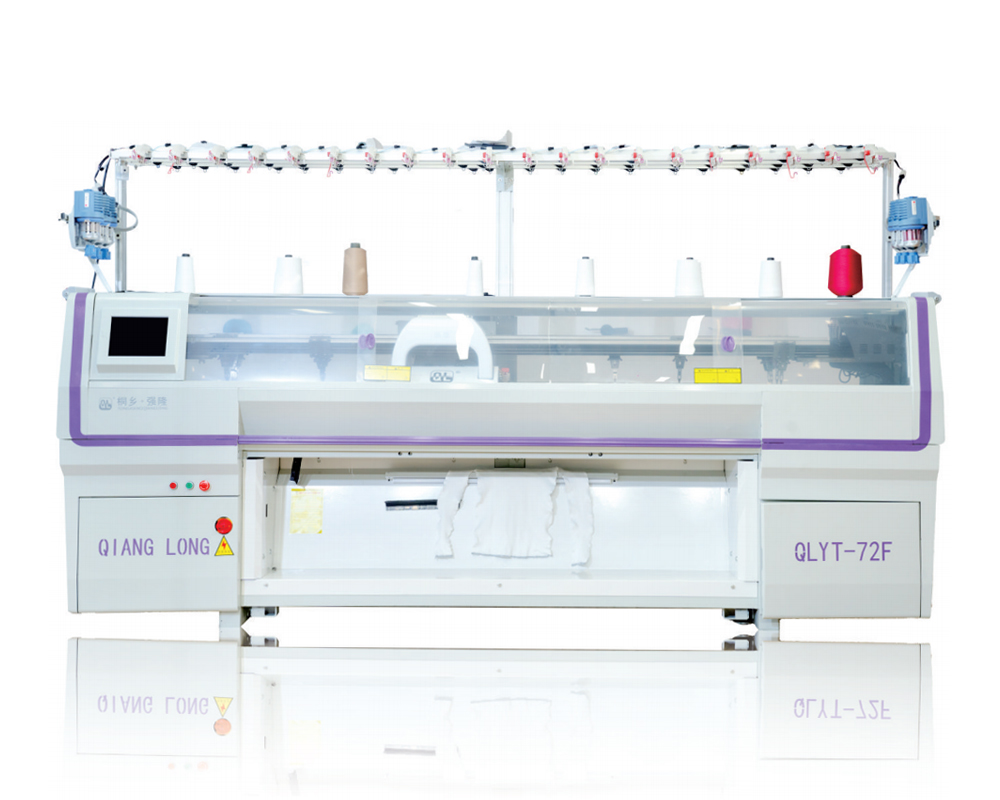

Tongxiang Qianglong Machinery Co., Ltd. is high-tech China wholesale computerized flat knitting machine manufacturers, specialized in designing, developing, and manufacturing Knitting Machinery..

In the ever-evolving world of textile manufacturing, the straight double computerized flat knitting machine stands out as a groundbreaking innovation. Known for its precision, efficiency, and versatility, this machine has redefined the production process for knitted fabrics. From fashion garments to technical textiles, its capabilities are transforming industries worldwide.

The straight double computerized flat knitting machine is a specialized knitting machine designed for the production of double-layered fabrics. Unlike traditional flat knitting machines, it integrates advanced computerized controls, enabling precise customization and intricate design creation.

The machine can knit two layers simultaneously, offering versatility for creating reversible fabrics, seamless garments, and multi-functional textiles.

Equipped with a sophisticated computer system, this machine allows for automated pattern programming, reducing human error and enhancing design complexity.

Available in various gauges (needle spacings), the machine accommodates a wide range of yarn types and fabric densities.

Advanced motors and controllers ensure efficient production, significantly reducing manufacturing time.

The touchscreen interface and intuitive software make it accessible even for operators with limited technical expertise.

Modern designs incorporate energy-saving features, making the machine more environmentally friendly.

Computerized programming ensures consistent stitch quality and precise replication of complex patterns.

The ability to easily program designs allows for quick adaptation to market trends and consumer demands.

While the initial investment may be high, the reduced labor costs, material waste, and increased production speed lead to long-term savings.

The dual-layer knitting capability doubles output without compromising quality.

Minimal waste during the knitting process aligns with the growing demand for sustainable manufacturing practices.

Garments: The machine is widely used for producing sweaters, cardigans, dresses, and other knitwear with intricate patterns.

Accessories: Hats, scarves, and gloves are crafted with precision and variety.

Sportswear: Functional fabrics with moisture-wicking and thermal properties are seamlessly produced.

Medical Textiles: Compression garments and bandages benefit from the precision and customization offered by the machine.

Decorative Items: Throws, cushion covers, and blankets are manufactured with intricate designs and double-layer structures.

Upholstery Fabrics: Durable and aesthetic fabrics for furniture applications.

Protective Gear: Fire-resistant and high-strength fabrics are created for industrial safety applications.

Automotive Interiors: Textiles for seat covers, door panels, and dashboards.

The advanced technology comes with a significant upfront cost, which may be a barrier for small manufacturers.

Operators require training to fully utilize the machine's capabilities.

Regular servicing and updates are essential to maintain optimal performance.

Integration of sensors and conductive yarns into fabrics produced by these machines opens new possibilities for wearable technology and IoT applications.

Future models may incorporate artificial intelligence to optimize design programming and production efficiency further.

Continued advancements in energy efficiency and the use of recycled materials will align with global sustainability goals.

Fully automated systems will enhance productivity and reduce reliance on manual interventions.

English

English 简体中文

简体中文

Chinese

Chinese English

English