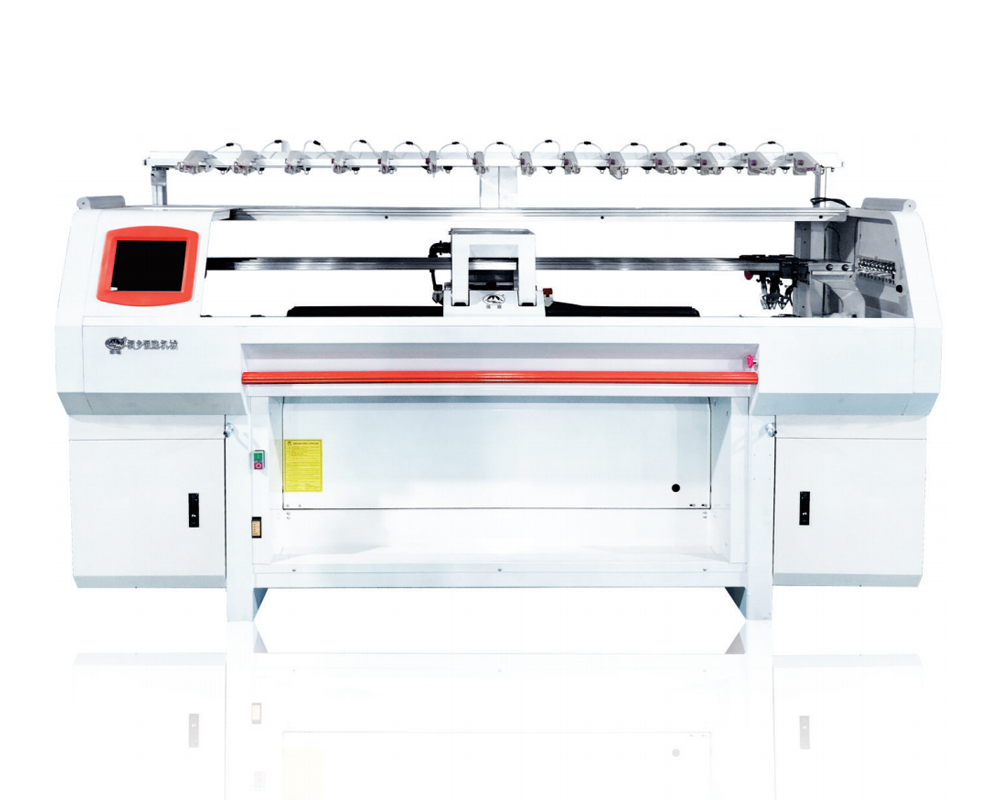

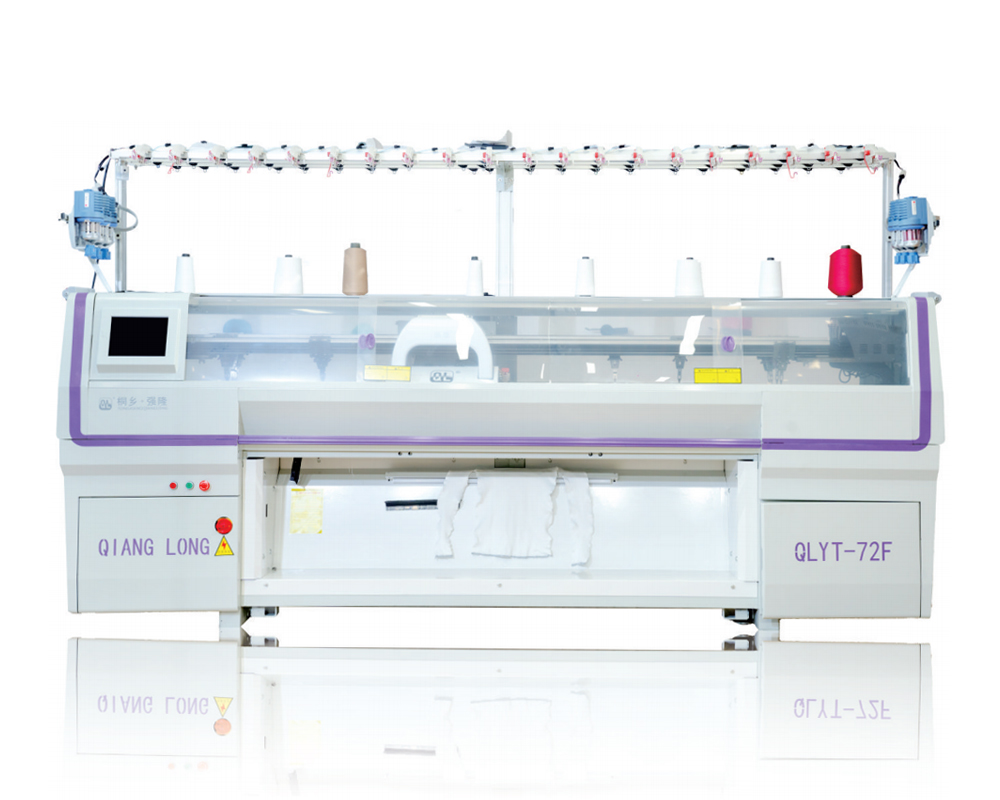

Tongxiang Qianglong Machinery Co., Ltd. is high-tech China wholesale computerized flat knitting machine manufacturers, specialized in designing, developing, and manufacturing Knitting Machinery..

In the modern textile industry, automation and intelligence are becoming the core driving force for the development of the industry. As an important breakthrough in the field of knitting machinery, the Three-system Computerized Flat Knitting Machine has become an important equipment to promote the upgrading of the knitting industry with its high efficiency, versatility and excellent product performance. The emergence of this machine not only improves production efficiency, but also opens up new possibilities for knitwear design and application.

The three-system computerized flat knitting machine is an advanced knitting machinery equipment with three independent knitting systems, which can perform multiple process operations at the same time, such as weaving of fabrics, pattern making and garment forming. Compared with traditional single-system or double-system flat knitting machines, the three-system design greatly improves production efficiency and the processing capacity of complex processes, while realizing high-precision operation and intelligent design of patterns through computer control.

The three independent knitting systems can work at the same time, greatly improving production efficiency. For knitting tasks with complex patterns or multiple processes, multiple steps can be completed in one knitting.

It supports multi-color yarn knitting and is suitable for the production of high-end knitwear.

Equipped with advanced computer control systems, it supports the precise design of complex patterns and weaving processes.

It can quickly adjust process parameters through software to reduce human errors in the production process.

It can be used to produce a variety of products, such as knitted clothing, home textiles, sportswear and medical textiles. It supports seamless molding technology, reduces subsequent processing links, reduces costs and improves product quality.

Reduce yarn waste and energy consumption through efficient design, in line with the concept of green production.

Provides a variety of automation functions, such as waste yarn recovery and real-time monitoring, to further enhance sustainability.

Wide range of applications

High-end customized knitted clothing: Through the intelligent functions of the three-system flat knitting machine, mass production of complex patterns, three-dimensional patterns and unique designs can be achieved.

Sportswear: Elastic and functional knitted fabrics can be achieved through precise control to meet the needs of high-performance clothing.

It can produce high-end knitted blankets, sofa covers and cushions and other household items, which are both comfortable and artistic.

Functional textiles

Support the production of high-performance medical products such as elastic fabrics and pressure socks.

Industrial textiles: such as filters, sound insulation fabrics, etc.

Market drivers and industry trends

The market demand for three-system computer flat knitting machines is growing rapidly. According to relevant data, the annual compound growth rate of the global knitting machinery market is expected to reach more than 6% in the next five years, among which high-end automated equipment such as three-system flat knitting machines occupy the main market share.

Consumer demand for high-end knitwear is growing

People are increasingly pursuing the quality and personalization of clothing and household items, which provides a broad market for the application of three-system flat knitting machines.

The new generation of three-system flat knitting machines has made breakthroughs in precision and production efficiency, while the manufacturing cost has gradually decreased, making it easier for small and medium-sized enterprises to accept.

With the help of Internet of Things and artificial intelligence technology, three-system flat knitting machines can achieve remote monitoring, data analysis and production optimization, further improving efficiency and flexibility.

In the future development of the textile industry, three-system computer flat knitting machines will play a vital role:

It provides designers with more possibilities, enabling complex knitting patterns and functional fabrics to be realized.

Efficient, energy-saving and intelligent equipment will promote the transformation of traditional textile enterprises to modernization and improve international competitiveness.

Driven by the sustainable development goals, the low energy consumption and high output characteristics of the three-system flat knitting machines are in line with the trend of green transformation in the global textile industry.

The three-system computer flat knitting machine is not only an advanced textile equipment, but also a representative of the intelligence and efficiency of the modern textile industry. Its emergence not only meets the market demand for high-end knitwear, but also brings more innovation opportunities to the industry. In the future, with the further advancement of technology and the continuous expansion of the market, the three-system computerized flat knitting machine is expected to become an indispensable production tool for global textile companies, leading the textile industry into a new intelligent era.

English

English 简体中文

简体中文

Chinese

Chinese English

English