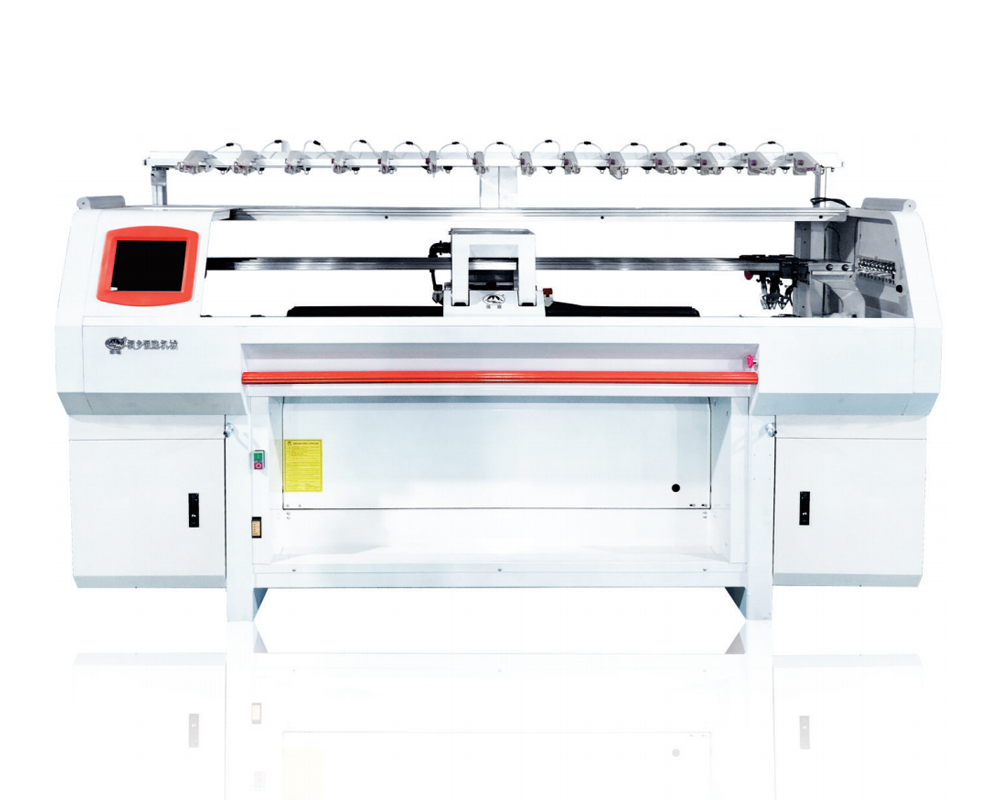

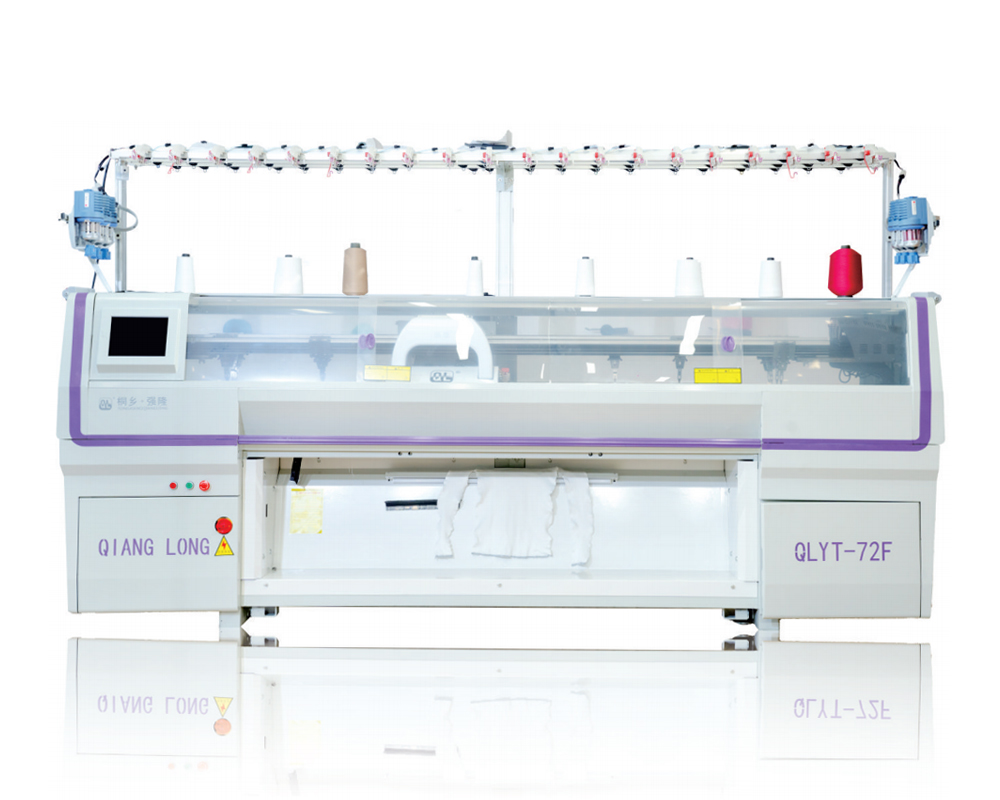

Tongxiang Qianglong Machinery Co., Ltd. is high-tech China wholesale computerized flat knitting machine manufacturers, specialized in designing, developing, and manufacturing Knitting Machinery..

In the knitting industry, technological advances continue to drive the improvement of production efficiency and product quality. The collar knitting machine is a product of such technological innovation. It is specially used to produce various collars, including round collars, V-necks, high collars, etc.

The collar knitting machine is a highly automated knitting equipment that uses programming control to achieve precise knitting of collars. This machine is usually equipped with multiple needles and corresponding control mechanisms, which can knit according to preset patterns and sizes. The working principle of the collar knitting machine is based on the basic technology of knitting, that is, the fabric is formed by the up and down movement of the needle and the interweaving of the yarn.

Compared with traditional hand knitting, the collar knitting machine can greatly increase the production speed and reduce labor costs.

The size and shape of the machine-knitted collar are more uniform, reducing human errors.

Modern collar knitting machines can quickly change patterns and sizes to meet the needs of different orders.

The edges of the machine-knitted collars are smoother, reducing the problems of thread ends and unevenness.

The collar knitting machine can easily achieve complex patterns and structures, providing designers with more creative space.

Due to the high efficiency of collar knitting machines, knitting factories can take on larger orders and meet market demand.

The collars knitted by machines are more delicate, which improves the overall quality of the finished garments.

Designers can use collar knitting machines to achieve more innovative designs and promote the development of the fashion industry.

Automated production reduces the dependence on skilled workers and helps to reduce production costs.

Automated equipment is generally more energy-efficient, which helps to reduce energy consumption and carbon emissions.

Although the collar knitting machine brings many advantages, it also faces some challenges:

With the rapid development of technology, the collar knitting machine needs to be constantly updated to adapt to new production needs.

Operating the collar knitting machine requires certain technical knowledge, and companies need to train their employees.

The maintenance and repair of automated equipment may require professional technical support, which adds additional costs.

As an important technology in the knitting industry, the collar knitting machine has played an important role in improving production efficiency, ensuring product quality and promoting design innovation. With the continuous advancement of technology, we can foresee that the collar knitting machine will have a wider application in the future, bringing more changes and development opportunities to the knitting industry.

English

English 简体中文

简体中文

Chinese

Chinese English

English